- Call Us 800-44-geary

-

Locations

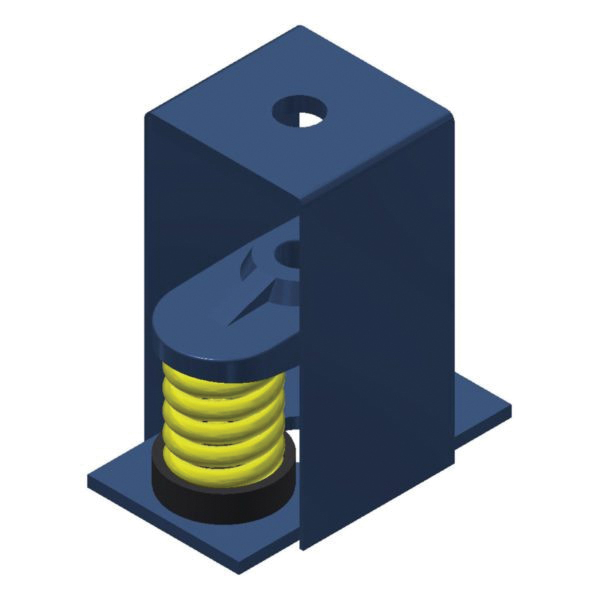

We reduced these problems by writing specifications and manufacturing hangers with the hole in the bottom of the hanger box as large as the ID of the spring. The HS spring hangers evolved using our standard A, B and C springs and seating them in LDS cups with projecting bushings to line the hole in the lower end of the box. A, B and C springs are designed for horizontal stiffness as described on Page 1, 4, 5 and 8 of Bulletin SLF-200, so they do not fall over or buckle. Centering the spring in the acoustical cup made steel-to-steel contact of the rod and the top steel cup unimportant and put the rubber in the right location on the leaving end of the spring.

Mason Industries Spring Vibration Hanger, Model: HS, 113 lb, 3-1/2 in Lower Rod Penetration, 113 in-lb Spring Constant, 3/8 in Maximum Rod Dia, 1 in Rated Deflection, 2-7/8 in Width, 4-1/4 in Height, Steel, Yellow

| Model | : | HS |

| Capacity | : | 113 lb |

| Lower Rod Penetration | : | 3-1/2 in |

| Spring Constant | : | 113 in-lb |

| Maximum Rod Diameter | : | 3/8 in |

| Rated Deflection | : | 1 in |

| Width | : | 2-7/8 in |

| Height | : | 4-1/4 in |

| Material | : | Steel |

| Color | : | Yellow |

- LDS rubber spring cup with a projecting bushing to prevent steel to steel contact

- LDS stands for low dynamic stiffness bridge bearing natural rubber to minimize noise and vibration transmission

- All springs have additional travel to solid equal to 50% of rated deflection

Catalog

Catalog